DESCALING CHEMICALS

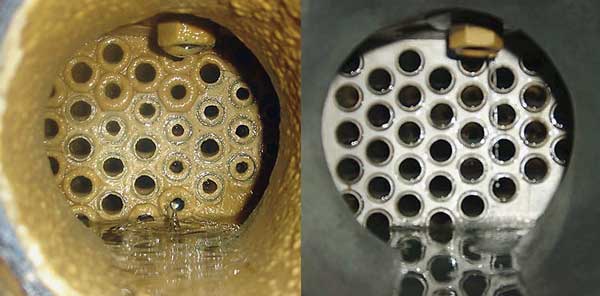

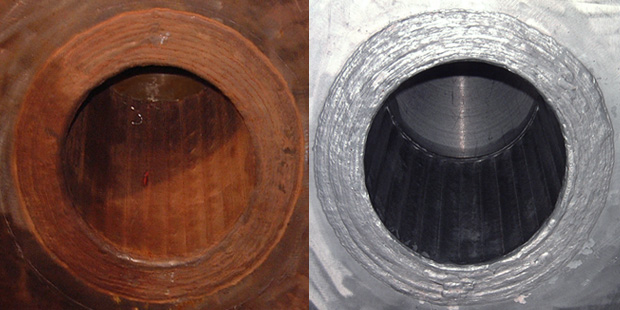

Cleaning industrial equipment is an essential operation to keep the heat transfer surfaces clean and in efficient working condition, descaling is required from time to time to remove the scale or any deposit from the heat transfer surfaces. Watersy India Technologies have developed descaling chemicals which are affective and compatible to all kind of metallurgy and even remove very hard deposits or oxides in the heat transfer surfaces.

Our Range Of Products :

- Descaling Compound for MS Metallurgy

- Descaling Compound for Copper Metallurgy

- Scale Softner

- Passivator After Descaling

PICKLING INHIBITOR

A large number of pickling inhibitors have been developed and used for application to various system depending upon the type of corrosion the Watersy India Technologies have developed pickling inhibitor which are affective in all circumstances protecting the bare metal surface and without neutralization or adverse affect on de-scaling chemical the some of our pickling inhibitor are

Our Range Of Products :

- Inhibitor for HCL

- Inhibitor for H2SO4

- Inhibitor for HNO3

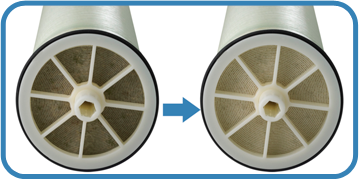

RO membrane CIP

In normal operation, the membrane in reverse osmosis elements can become fouled by suspended solids, microorganisms, and mineral scale. These deposits build up during operation and cause loss in water output or salt rejection, or both. Regular cleaning of the membrane elements minimizes the loss of performance and extends membrane life. Applied Membranes, Inc. has formulated its own proprietary membrane cleaning chemicals. These products are a result of over 30 years of hands-on experience of our engineers and chemists. We offer technical expertise and assistance in troubleshooting and cleaning of RO membranes to give you an optimum system performance.

Non-Acid Coil Cleaner and Brightener for AHU Aluminum Coil

Coil cleaner and brightener removes energy-robbing dirt, soil, atmospheric oxide deposits and encrusted residue from air conditioning evaporator and condenser coils and fins.

Powerful alkaline cleaner and brightener

• Less harmful to equipment and personnel than acid-type aluminum coil cleaners; also easier to apply.

• Fast acting-works in 3 to 5 minutes.

• Mixes with upto 25 parts water for economical application.

• Foaming action allows the product to penetrate and cling to vertical surfaces for longer, more effective cleaning.

• Strips off oxide deposits and entrusted dirt without harming the coils.

Application

Dilute up to 1:25 with water and apply with a pump sprayer at low pressure. Thoroughly wet down the coils. Depending on the density of the oxidation, allow the product to work 3-4 minutes. Rinse with a high-pressure sprayer. Rinse a second time to ensure the complete removal of the cleaning solution before using the coils.

Not recommended for use where paint damage would be a problem. May damage seals. Do not use on polished or anodized aluminum. Do not use on automotive finishes.

DILUTION RATES BY APPLICATION

•1:25 Normal cleaning

•1:20 Cleaning air conditioning coils

•1:10 Coil brightening

•1:8 Badly pitted / oxidized surfaces

Our Range Of Products :

- Non-Acid Coil Cleaner & Brightner

- Coil Cleaner & Brightner

- Organic Neutralizer

Media & Resin Cleaning Chemicals

Water softener resin is extremely porous, which is beneficial because it allows for more surface area to capture calcium and other metals in source water. Surprisingly, 99% of ion exchange actually happens in the interior of the bead. Resin beads, ranging in size from 16 to 50 mesh, are abused daily during the backwash process and by contaminants in the source water. Resin could last much longer in these hostile environments with a few fairly inexpensive solutions.